Why Polycarbonate Sheets Are a Practical Choice

Introduction to Polycarbonate Sheets

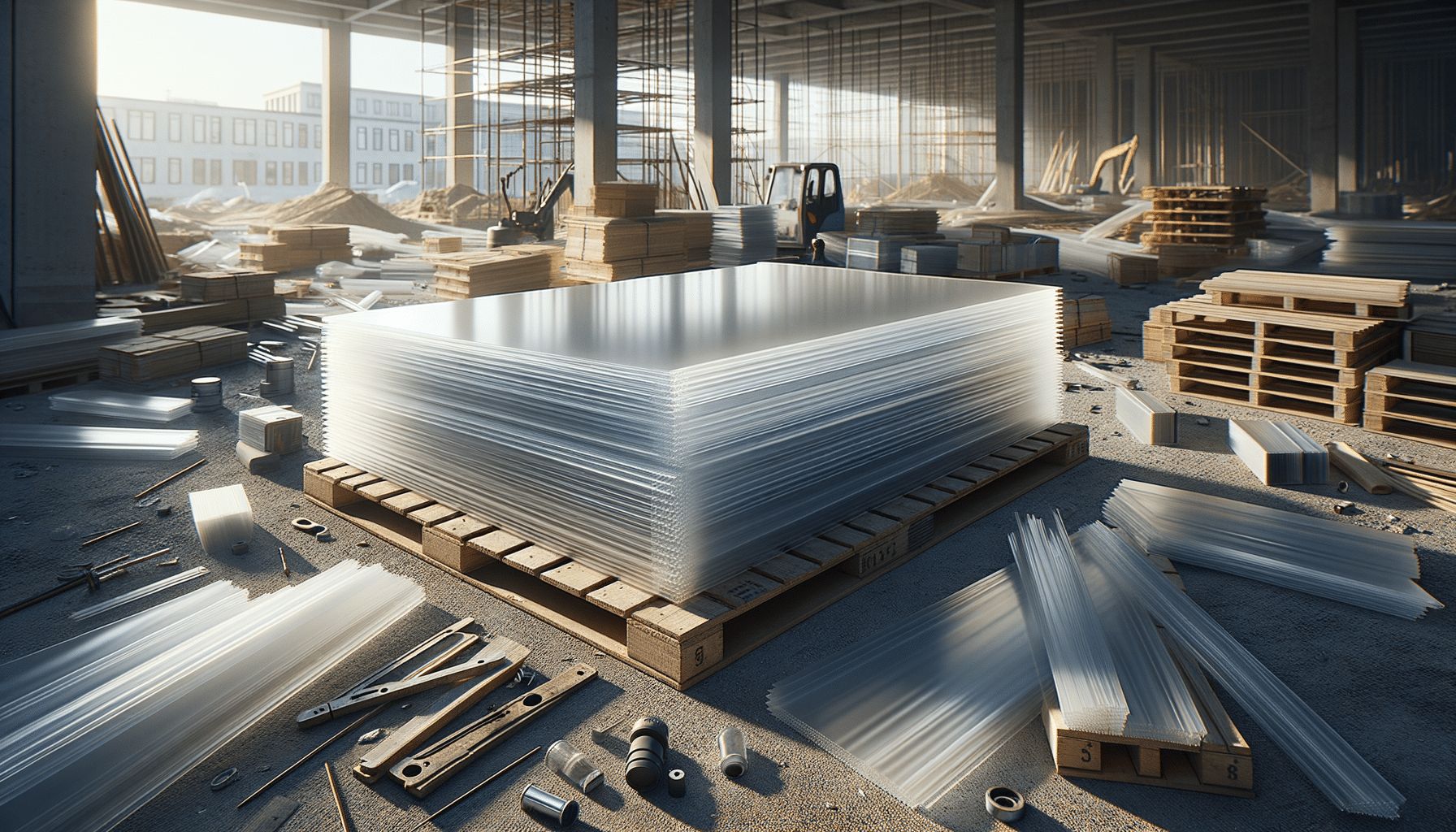

Polycarbonate sheets, commonly referred to as polycarbonate-board, have become a staple in various industries due to their remarkable properties. These sheets are known for being lightweight yet incredibly strong, offering a viable alternative to traditional materials like glass. The importance of polycarbonate sheets lies in their versatility and durability, making them suitable for a wide range of applications. From construction to interior design, these sheets are valued for their ability to withstand impact while providing excellent transparency and UV resistance.

The relevance of polycarbonate sheets in today’s world cannot be overstated. As industries seek materials that combine strength, flexibility, and cost-effectiveness, polycarbonate emerges as a top contender. Its unique properties make it a preferred choice for architects, designers, and DIY enthusiasts alike, who are constantly in search of innovative solutions that do not compromise on quality or safety.

Properties and Advantages of Polycarbonate Sheets

Polycarbonate sheets, or polycarbonate-board, are known for their exceptional properties that make them a preferred choice in various applications. One of the primary advantages is their high impact resistance. Unlike glass, polycarbonate is less likely to shatter upon impact, which enhances safety in environments where breakage could pose significant risks. This makes them particularly useful in areas prone to extreme weather conditions or high traffic.

Another significant advantage is their weight. Polycarbonate sheets are much lighter than glass, which simplifies handling and installation. This characteristic is especially beneficial in construction and renovation projects, where ease of installation can lead to reduced labor costs and shorter project timelines. Additionally, polycarbonate offers excellent thermal insulation, which can contribute to energy efficiency in buildings.

Furthermore, polycarbonate sheets provide outstanding UV protection, making them suitable for outdoor applications. They can effectively block harmful UV rays while allowing natural light to pass through, which is ideal for greenhouses, skylights, and sunrooms. The durability of polycarbonate also means that it can withstand harsh environmental conditions without degrading over time, ensuring longevity and sustained performance.

Applications of Polycarbonate Sheets

The applications of polycarbonate sheets, or polycarbonate-board, are vast and varied, demonstrating their versatility across different sectors. In the construction industry, these sheets are commonly used for roofing, glazing, and cladding due to their strength and transparency. They provide an excellent alternative to glass, offering similar aesthetic benefits without the associated fragility.

In the automotive industry, polycarbonate is frequently used for headlight lenses, windows, and sunroofs. Its lightweight nature contributes to fuel efficiency, while its durability ensures that components can withstand the rigors of daily use. Additionally, the material’s ability to be easily molded allows for creative design possibilities, enabling manufacturers to produce components that are both functional and visually appealing.

Polycarbonate sheets are also popular in the signage industry. Their clarity and ability to be printed on make them ideal for creating vibrant, eye-catching signs that can endure outdoor exposure. Furthermore, in electronics, polycarbonate is used for protective covers and casings, providing a robust shield against physical damage while maintaining a sleek appearance.

Comparing Polycarbonate to Other Materials

When comparing polycarbonate sheets, or polycarbonate-board, to other materials, several distinct advantages become apparent. Compared to glass, polycarbonate is significantly more impact-resistant and flexible. This flexibility not only reduces the risk of breakage but also allows for more dynamic design applications, such as curved surfaces.

In comparison to acrylic, polycarbonate is more durable and offers better resistance to heat and weathering. While acrylic can offer superior optical clarity initially, polycarbonate maintains its clarity and structural integrity over a longer period, especially in challenging environments. This makes it a more reliable choice for applications that require longevity.

Moreover, polycarbonate’s lightweight nature gives it an edge over traditional materials like metal. While metals may offer strength, they are often heavy and prone to corrosion. Polycarbonate, on the other hand, is corrosion-resistant and requires minimal maintenance, making it a cost-effective solution for many applications.

Conclusion: The Future of Polycarbonate Sheets

The future of polycarbonate sheets, or polycarbonate-board, looks promising as industries continue to prioritize materials that offer a balance of performance and sustainability. With ongoing advancements in manufacturing processes, polycarbonate is becoming even more versatile and accessible, paving the way for innovative applications that were previously unattainable.

As the demand for eco-friendly and efficient building materials grows, polycarbonate is poised to play a crucial role in shaping modern architecture and design. Its ability to provide safety, durability, and aesthetic appeal makes it a top choice for those looking to embrace sustainable practices without compromising on quality.

In summary, polycarbonate sheets offer a practical solution for a wide range of applications, combining strength, flexibility, and cost-effectiveness. As industries evolve and new challenges arise, polycarbonate is well-positioned to meet the needs of the future, proving that it is not just a temporary trend but a lasting innovation in material science.