Why Polycarbonate Sheets Are a Practical Choice

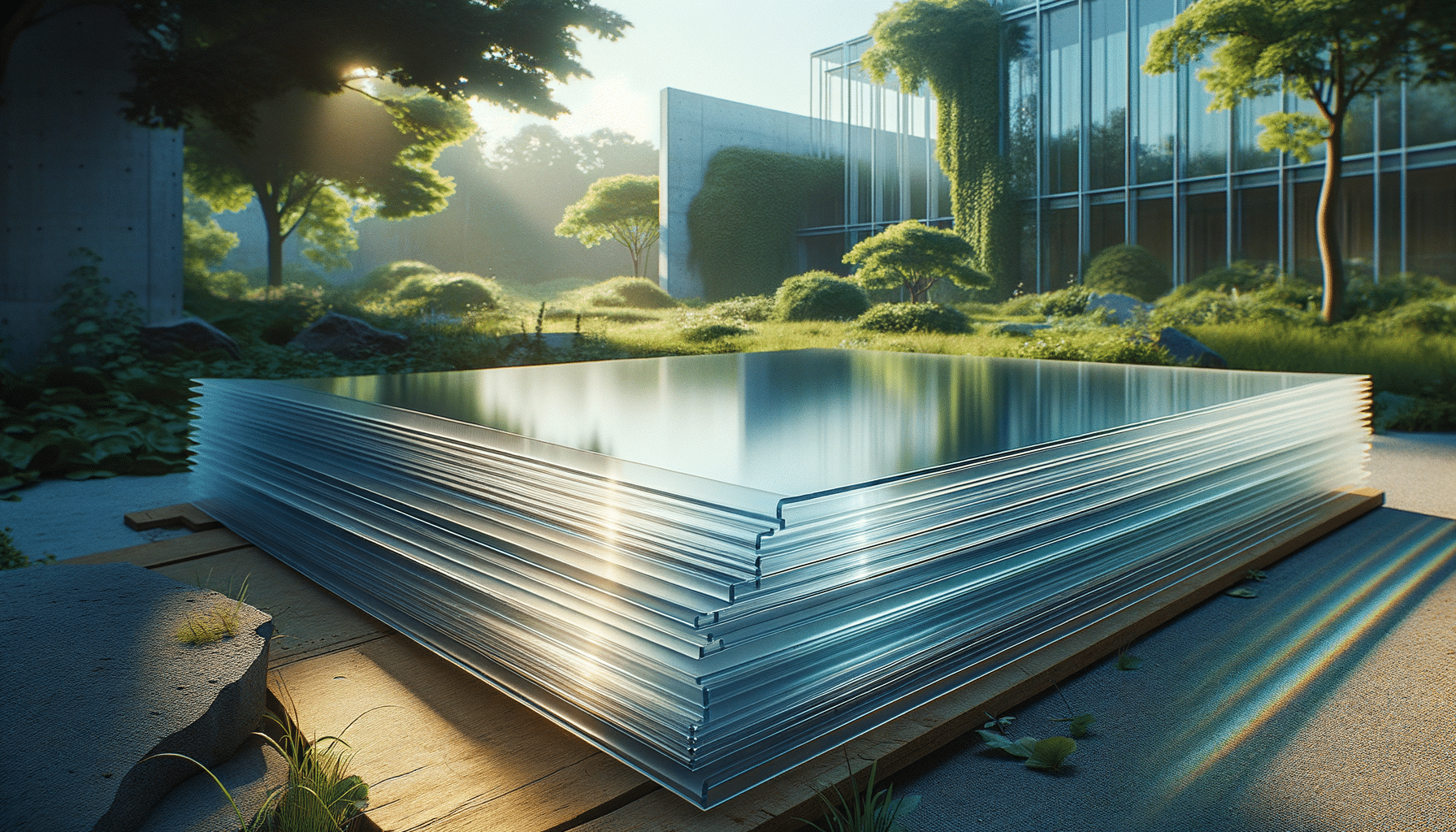

Introduction to Polycarbonate Sheets

Polycarbonate sheets have become a staple in construction and design due to their impressive properties. These sheets offer a unique combination of strength, flexibility, and transparency, making them a preferred material for various applications. Unlike traditional glass, polycarbonate-board provides a lightweight yet robust alternative that is easier to handle and install. This material’s versatility extends beyond just construction; it is also widely used in the automotive and aerospace industries, among others. Its ability to withstand extreme temperatures and impacts without shattering makes it a safe and reliable choice for many projects.

Advantages of Using Polycarbonate Sheets

The benefits of using polycarbonate-board are numerous and varied, contributing to its popularity across different sectors. One of the primary advantages is its exceptional impact resistance, which is significantly higher than that of glass. This makes it an ideal material for safety applications, such as in protective barriers and eyewear. Additionally, polycarbonate sheets are lightweight, reducing the structural load and making them easier to transport and install. Their flexibility allows for creative design opportunities, as they can be easily molded into various shapes without compromising strength.

Moreover, polycarbonate-board offers excellent thermal insulation, aiding in energy efficiency for buildings. It is also resistant to UV radiation, which prevents yellowing and degradation over time, ensuring longevity. This durability is complemented by its fire resistance, adding an extra layer of safety in applications where fire hazards are a concern. The combination of these properties makes polycarbonate sheets a practical choice for a wide range of uses.

Applications of Polycarbonate Sheets

Polycarbonate-board is utilized in numerous applications due to its outstanding characteristics. In the construction industry, it is often used for skylights, roofing, and cladding due to its transparency and durability. Its lightweight nature makes it ideal for greenhouse glazing, where weight is a critical factor. The automotive industry employs polycarbonate sheets in headlamps and interior components, benefiting from their impact resistance and clarity.

In the electronics sector, polycarbonate is used in the manufacturing of CDs, DVDs, and other optical discs. Its excellent electrical insulation properties make it suitable for various electronic components and housings. Furthermore, polycarbonate sheets are used in the production of bulletproof windows and enclosures, showcasing their exceptional strength and safety features. The versatility of polycarbonate-board continues to drive innovation across multiple industries.

Comparing Polycarbonate to Other Materials

When comparing polycarbonate-board to other materials such as acrylic and glass, several distinctions become apparent. Glass, while offering clarity and hardness, is heavy and prone to shattering. In contrast, polycarbonate is much lighter and virtually unbreakable, providing a safer option for environments where impact resistance is crucial. Acrylic, another popular material, offers good optical clarity but lacks the impact resistance and thermal stability of polycarbonate.

Polycarbonate’s superior properties make it a more versatile and durable choice for many applications. Its ability to withstand temperature fluctuations and environmental stress without compromising integrity sets it apart from other transparent materials. Additionally, polycarbonate’s ease of fabrication and installation makes it a more cost-effective solution in the long run, as it reduces labor and maintenance costs.

Conclusion: The Future of Polycarbonate Sheets

As industries continue to evolve and demand more from materials, polycarbonate-board stands out as a forward-thinking solution. Its blend of strength, flexibility, and transparency makes it suitable for a wide array of applications, from construction to electronics. The ongoing advancements in polycarbonate technology promise even greater enhancements in performance and sustainability.

With its proven track record and adaptability, polycarbonate sheets are poised to remain a vital component in both current and future projects. As environmental concerns rise, the development of more eco-friendly polycarbonate options will likely become a focus, ensuring this material’s relevance and utility for years to come.