Buying Guide for Scissor Lifts

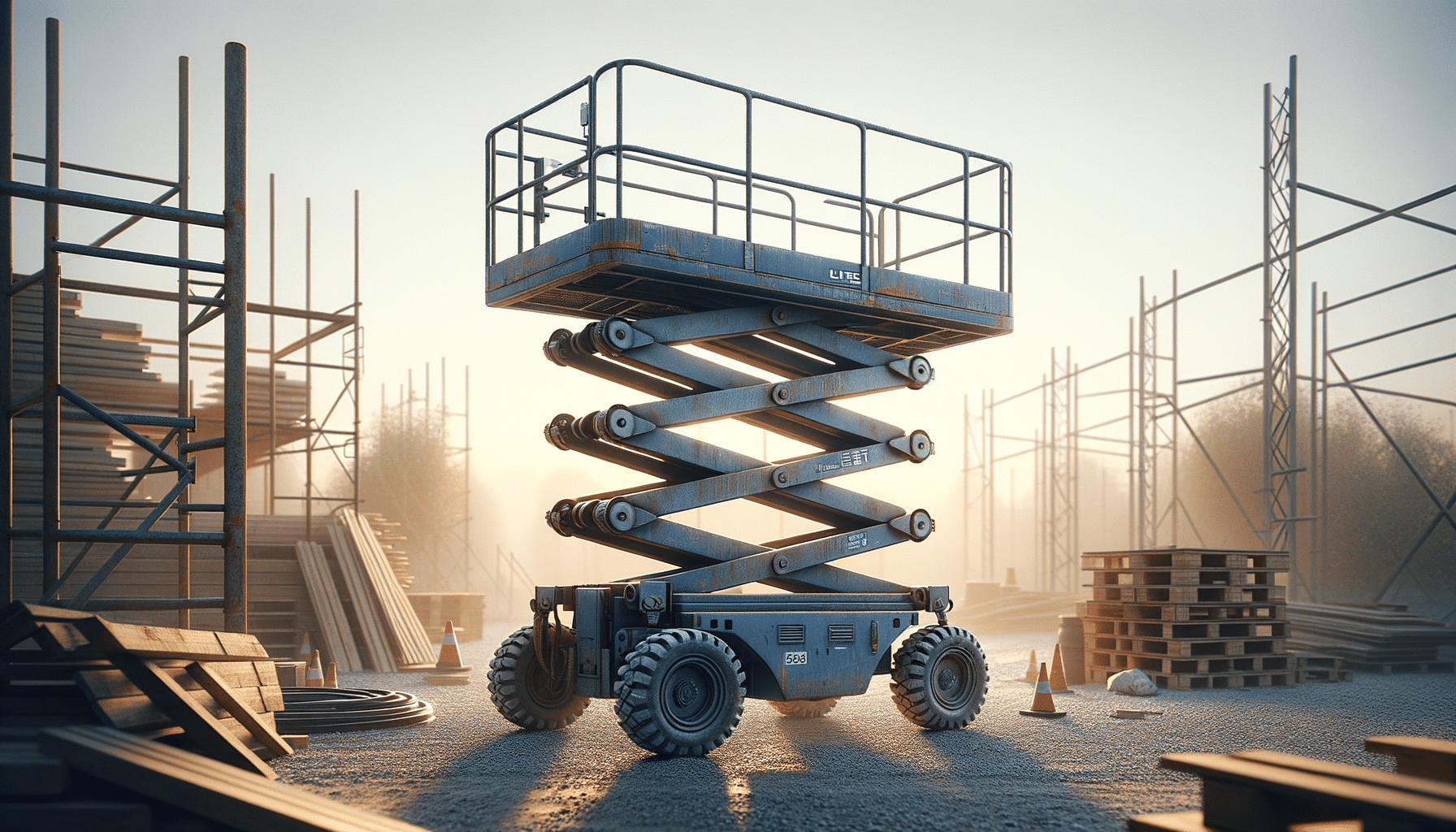

Introduction to Scissor Lifts

Scissor lifts are essential tools in various industries, offering a stable and efficient means of lifting workers and equipment to elevated work areas. With their distinctive X-shaped design, these lifts provide a reliable platform for tasks that require height, such as construction, maintenance, and installation. Understanding the benefits and functionalities of a scissor lift can significantly enhance workplace safety and productivity.

The stability of a scissor lift comes from its crisscrossing supports. This design allows it to extend upward in a straight, vertical motion, providing a secure base for workers. They are particularly favored for their ease of use and versatility in different environments, from indoor warehouses to outdoor construction sites. This article delves into the various aspects of scissor lifts, helping you make informed decisions when considering their purchase or rental.

Types and Applications of Scissor Lifts

Scissor lifts come in various types, each designed to meet specific operational needs. The most common types include electric scissor lifts and rough terrain scissor lifts. Electric scissor lifts are ideal for indoor use, providing quiet, emission-free operation. They are perfect for environments where noise and air quality are concerns, such as warehouses and factories.

On the other hand, rough terrain scissor lifts are equipped with heavy-duty tires and stronger engines, making them suitable for outdoor use on uneven surfaces. These lifts are invaluable on construction sites where stability and mobility over rugged terrain are crucial. Their robust design ensures they can handle the demanding conditions often found in outdoor settings.

The versatility of scissor lifts extends to their applications. They are used in construction, facility maintenance, and even event management. Whether it’s installing lighting in a theater or conducting high-level repairs, a scissor lift provides a safe and efficient platform for workers.

Safety Features and Considerations

Safety is paramount when operating any lifting equipment, and scissor lifts are no exception. Modern scissor lifts are equipped with numerous safety features to protect operators and bystanders. These include guardrails, emergency stop buttons, and overload protection systems. The guardrails provide a secure boundary, preventing falls, while emergency stop buttons allow for immediate cessation of operation in case of an emergency.

Overload protection systems are crucial as they prevent the lift from operating if the weight limit is exceeded, thereby avoiding potential accidents. Regular maintenance and inspection of scissor lifts further ensure their safe operation. Operators should be trained in proper use and familiar with the specific model they are handling to reduce the risk of accidents.

It is also important to consider the environment in which the scissor lift will be used. For instance, electric models are better suited for indoor use, where ventilation might be limited, while rough terrain models are more appropriate for outdoor work.

Cost and Economic Considerations

The cost of a scissor lift varies based on its type, size, and features. Electric scissor lifts tend to be more affordable than their rough terrain counterparts, primarily because they are designed for less demanding environments. However, investing in the right type of scissor lift can save money in the long run by improving efficiency and reducing the risk of workplace accidents.

When considering a purchase, it’s important to evaluate the potential return on investment. A scissor lift can enhance productivity by reducing the time and manpower required for tasks that involve height. Renting a scissor lift can be a cost-effective option for businesses that only need this equipment occasionally.

Moreover, many manufacturers offer financing options, making it easier to acquire a scissor lift without a significant initial outlay. By carefully assessing your operational needs and budget, you can choose a scissor lift that offers the best value for your investment.

Maintenance and Longevity

Regular maintenance is key to ensuring the longevity and reliable operation of a scissor lift. Routine checks should include inspection of the hydraulic systems, safety features, and mechanical components. Keeping the lift clean and lubricated also helps in preventing rust and wear.

Many manufacturers provide maintenance schedules and guidelines to help ensure that the equipment remains in optimal condition. Following these recommendations can prevent costly repairs and extend the lifespan of the lift. It’s also advisable to keep a maintenance log to track any repairs or replacements, which can be invaluable for troubleshooting and ensuring compliance with safety regulations.

In conclusion, a well-maintained scissor lift not only enhances safety but also maximizes efficiency, making it a valuable asset in any operation that requires working at height.