Buying Guide for Scissor Lifts

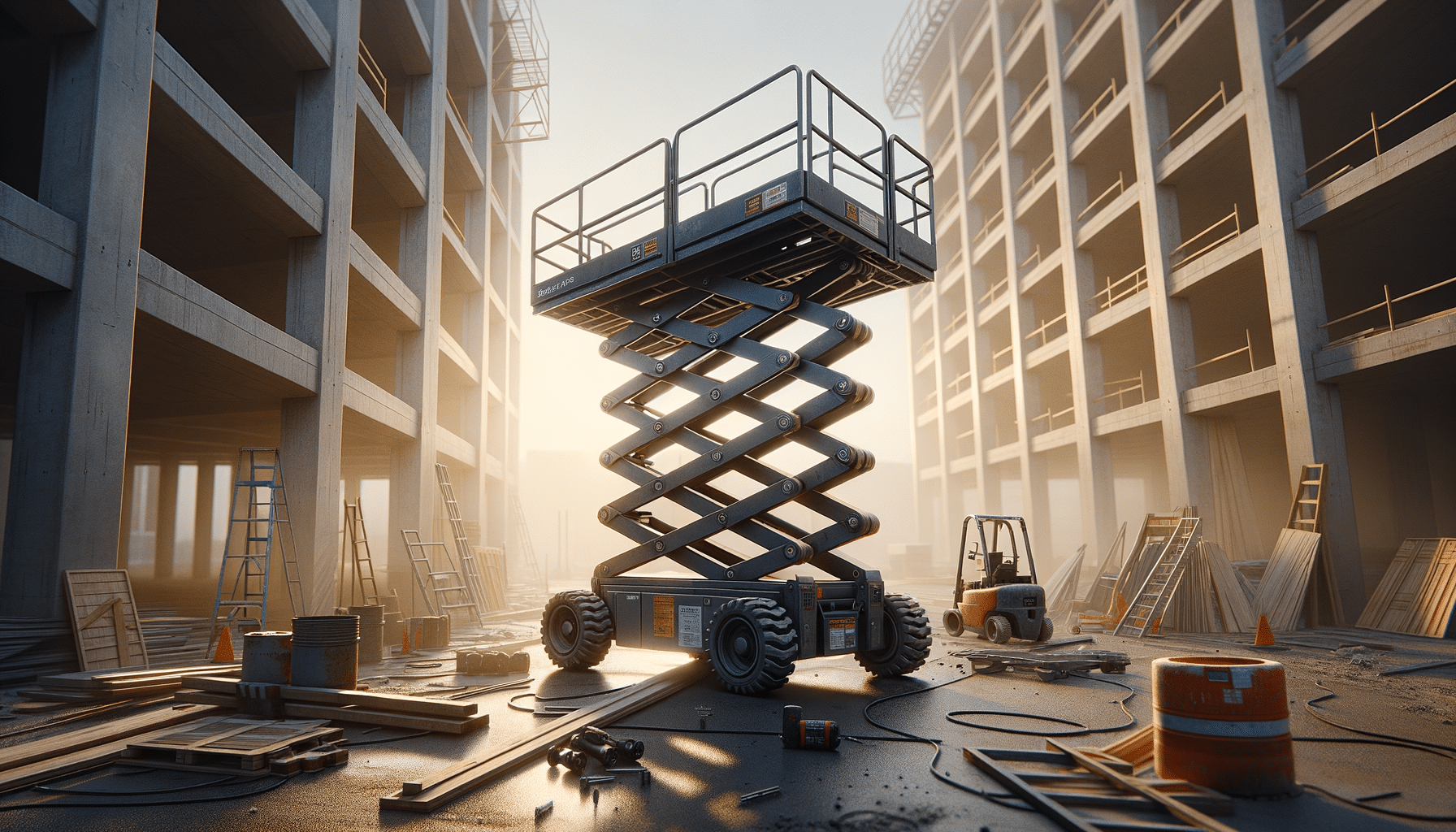

Introduction to Scissor Lifts

In the realm of industrial and construction equipment, the scissor lift stands out as a vital tool for reaching elevated areas safely and efficiently. Its distinctive X-shaped mechanism not only provides stability but also ensures ease of operation, making it a preferred choice for various tasks. Whether you are involved in maintenance, construction, or warehousing, understanding the benefits and functionalities of a scissor lift is crucial for optimizing productivity and ensuring safety.

The scissor lift’s design allows it to extend vertically, offering a stable platform for workers to perform tasks at heights. This article delves into the various aspects of scissor lifts, providing a comprehensive guide for potential buyers. From understanding the types and features to evaluating safety protocols, this guide aims to equip you with the knowledge needed to make an informed purchase decision.

Types of Scissor Lifts

Scissor lifts come in various types, each designed to cater to specific needs and environments. The most common types include electric, diesel, and hydraulic scissor lifts, each with its own set of advantages and limitations.

Electric scissor lifts are favored for indoor use due to their quiet operation and zero emissions. They are ideal for environments where noise and air quality are concerns, such as in warehouses and retail spaces. Diesel scissor lifts, on the other hand, are more powerful and are best suited for outdoor applications where rough terrain might be a factor. Their robust build and higher weight capacity make them suitable for construction sites.

Hydraulic scissor lifts utilize a system of hydraulic cylinders to achieve lift, providing smooth and reliable operation. They can be powered by either diesel or electricity, offering versatility in various applications. When choosing a scissor lift, it is essential to consider the specific requirements of your work environment to select the most appropriate type.

Features and Specifications

When considering the purchase of a scissor lift, it is important to evaluate its features and specifications to ensure it meets your operational needs. Key features to look for include platform height, lift capacity, and mobility.

The platform height determines the maximum reach of the scissor lift, which is a crucial factor depending on the tasks you intend to perform. Lift capacity is another critical consideration, as it dictates the amount of weight the lift can safely handle. This includes not only the weight of the workers but also any tools and materials they might be carrying.

Mobility is another important aspect, particularly if the scissor lift needs to be moved frequently between different job sites. Some models are equipped with features like four-wheel drive and automatic leveling systems, which enhance their maneuverability and stability on uneven surfaces. By carefully assessing these features, you can ensure that the scissor lift you choose will effectively support your operational requirements.

Safety Considerations

Safety is paramount when operating a scissor lift, as working at heights presents inherent risks. It is vital to adhere to safety protocols and guidelines to prevent accidents and injuries. One of the first steps is to ensure that operators are adequately trained and familiar with the lift’s controls and safety features.

Regular maintenance and inspections are crucial to ensure the scissor lift remains in optimal working condition. This includes checking for any signs of wear and tear, ensuring that safety mechanisms are functional, and addressing any mechanical issues promptly.

Additionally, the use of personal protective equipment (PPE) such as harnesses and helmets is essential when working on a scissor lift. By prioritizing safety, you can create a secure and efficient working environment that minimizes risks associated with elevated work.

Conclusion: Making an Informed Purchase

Purchasing a scissor lift is a significant investment that requires careful consideration of various factors, including the type, features, and safety protocols. By understanding the specific needs of your work environment and evaluating different options, you can select a scissor lift that enhances productivity while ensuring safety.

Whether you are in construction, maintenance, or warehousing, the right scissor lift can make a substantial difference in your operations. With the information provided in this guide, you are now equipped to make a well-informed decision that aligns with your operational goals and safety requirements.

Remember, a scissor lift is more than just a piece of equipment; it is a tool that, when used correctly, can transform the way you work at heights, offering efficiency, safety, and reliability.