Buying Guide for Scissor Lifts

Introduction to Scissor Lifts

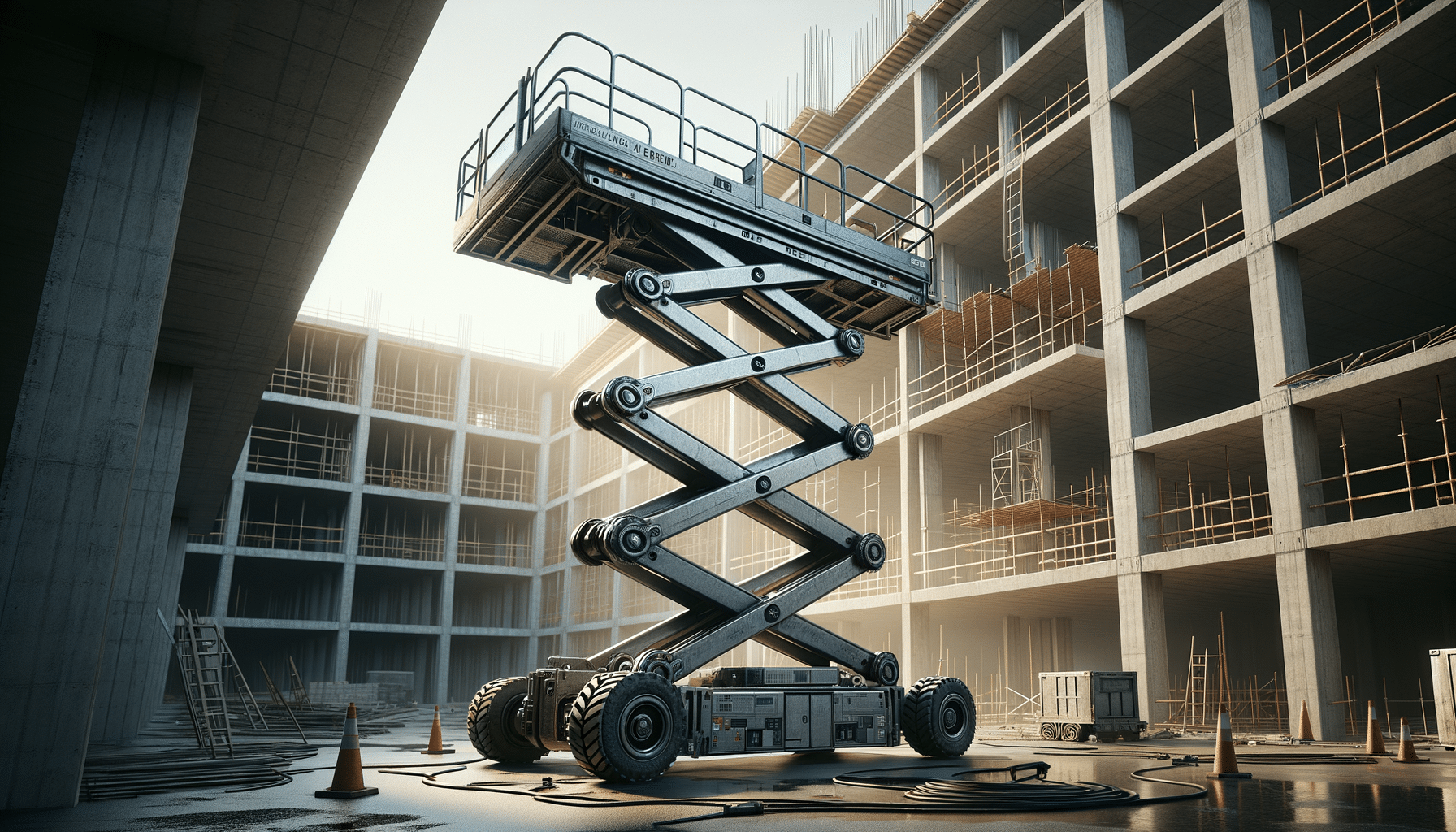

The scissor lift is a crucial piece of equipment in various industries, known for its ability to safely elevate workers and materials to different heights. This versatile machinery is characterized by its unique X-shaped design, which provides stability and efficiency in operations. Whether you’re involved in construction, maintenance, or any industry that requires elevated work, understanding the features and benefits of a scissor lift can enhance your productivity and safety.

Understanding the Mechanism

At the heart of a scissor lift’s functionality is its distinctive mechanism, which comprises crisscrossing metal supports that operate in a pantograph style. This design is not only visually striking but also mechanically efficient. The scissor lift expands vertically, powered by hydraulic, pneumatic, or mechanical systems, allowing for smooth elevation and descent. This mechanism ensures that the platform remains stable, even when extended to its full height. Critical components include the hydraulic cylinders, which provide the necessary force, and the platform, which supports the load. This reliable design makes the scissor lift a preferred choice for tasks that require precision and safety.

Applications in Various Industries

The scissor lift finds its applications across a multitude of sectors. In the construction industry, it facilitates tasks such as painting, electrical installations, and exterior building maintenance. Warehouses utilize scissor lifts for efficient stock management, enabling workers to reach high shelves safely. Furthermore, in the entertainment industry, scissor lifts are used for setting up stages and lighting rigs. Key benefits include:

- Enhanced safety with guardrails and safety features.

- Versatility in indoor and outdoor environments.

- Cost-effectiveness compared to other aerial work platforms.

These applications underscore the scissor lift’s role as an indispensable tool in operations that require height access.

Safety Features and Considerations

Safety is paramount when operating a scissor lift. These machines are equipped with several safety features designed to protect operators and bystanders. Key safety elements include emergency stop buttons, tilt sensors, and guardrails. Additionally, routine maintenance and inspections are crucial to ensure the lift’s reliability. Operators must be trained to handle the equipment, understanding load limits and safe operating procedures. By adhering to these safety protocols, users can minimize risks and ensure a secure working environment.

Choosing the Right Scissor Lift

Selecting the appropriate scissor lift involves considering several factors, including the intended use, required height, and environment. For indoor applications, electric scissor lifts are preferred due to their quiet operation and lack of emissions. Outdoor tasks might require diesel-powered lifts, which are robust and capable of handling rough terrains. Furthermore, assessing the lift’s weight capacity and platform size is essential to meet specific operational needs. By evaluating these aspects, businesses can invest in a scissor lift that enhances efficiency and meets safety standards.

Conclusion

The scissor lift is a vital asset for industries requiring safe and efficient elevation solutions. Its stable X-shaped design ensures reliability, while its versatility across various applications highlights its importance. When considering the purchase of a scissor lift, understanding its features, safety considerations, and operational requirements will guide you in making an informed decision. Ultimately, the right scissor lift can significantly contribute to the productivity and safety of your operations.