Buying Guide for Scissor Lifts

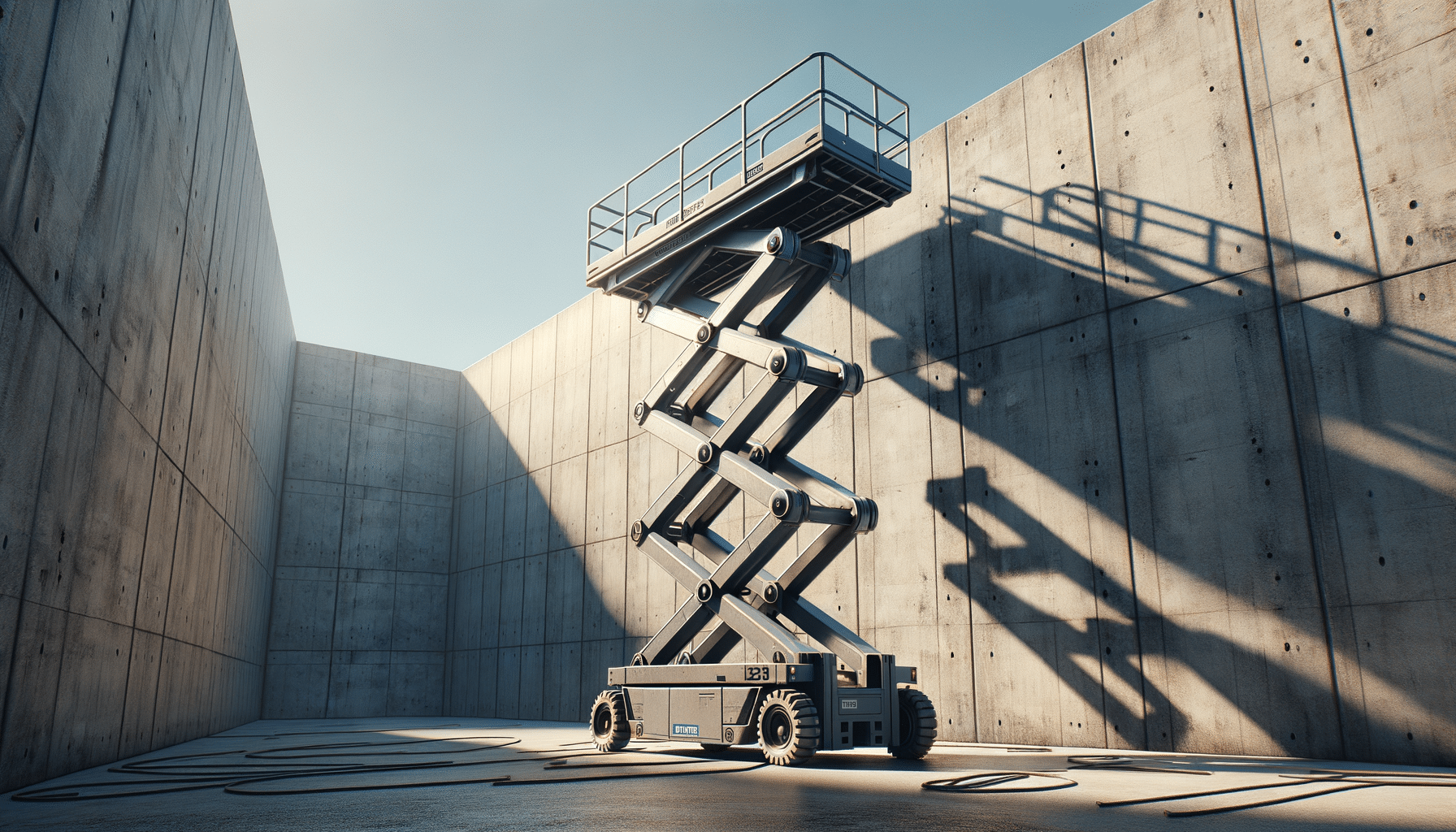

Introduction to Scissor Lifts

In the realm of industrial equipment, the scissor lift stands out as a versatile and essential tool. Known for its stable X-shaped design, this hydraulic platform is primarily used for lifting workers and materials to elevated work areas. The scissor lift is not just user-friendly but also designed with safety and efficiency in mind, making it a preferred choice for various industries including construction, maintenance, and warehousing.

Scissor lifts are crucial for tasks that require reaching certain heights safely, without the need for scaffolding or ladders. They are particularly beneficial in environments where space is limited, offering a compact solution that can be maneuvered easily. The importance of scissor lifts lies in their ability to enhance productivity while ensuring the safety of workers, thereby reducing the risk of workplace accidents.

Types and Models of Scissor Lifts

Scissor lifts come in various types and models, each designed to meet specific needs. The most common types include electric scissor lifts and diesel scissor lifts. Electric scissor lifts are ideal for indoor use due to their quiet operation and zero emissions. They are perfect for environments where noise and air quality are concerns, such as hospitals and shopping malls.

Diesel scissor lifts, on the other hand, are more powerful and suitable for outdoor construction sites. They can handle rough terrain and have a higher weight capacity, making them ideal for heavy-duty tasks. Some models are equipped with four-wheel drive capabilities, providing enhanced mobility on uneven surfaces.

Additionally, there are rough terrain scissor lifts that are specifically designed for challenging environments. These come with features such as larger tires and reinforced platforms to handle outdoor conditions effectively. When choosing a scissor lift, it’s important to consider the specific requirements of your project to select the most suitable model.

Safety Features and Considerations

Safety is a paramount consideration when operating a scissor lift. These machines are equipped with numerous safety features to ensure the protection of operators and bystanders. Key features include guardrails, non-slip surfaces, and emergency stop buttons. Guardrails prevent falls from the platform, while non-slip surfaces reduce the risk of slipping accidents.

Moreover, scissor lifts are designed with stability in mind. The X-shaped design ensures even weight distribution, minimizing the risk of tipping over. Many models also feature automatic leveling systems that adjust the platform to maintain stability on uneven surfaces.

Operators should be adequately trained to handle scissor lifts safely. Training should cover the proper use of controls, understanding load limits, and recognizing potential hazards in the work environment. Regular maintenance checks are also crucial to ensure that all safety mechanisms are functioning correctly.

Applications and Benefits

The applications of scissor lifts are vast and varied, making them indispensable in numerous industries. In construction, they are used for installing windows, painting walls, and repairing roofs. In warehouses, scissor lifts facilitate the easy stacking and retrieval of goods from high shelves.

One of the significant benefits of using a scissor lift is the increased efficiency it brings to tasks that require height. Workers can perform their duties more quickly and with less physical strain, improving overall productivity. Additionally, scissor lifts reduce the need for ladders and scaffolding, which can be cumbersome and time-consuming to set up.

Scissor lifts also contribute to a safer work environment. By providing a stable and secure platform, they significantly lower the risk of falls and other height-related accidents. This not only protects workers but also reduces the potential for costly insurance claims and downtime due to injuries.

Factors to Consider When Purchasing a Scissor Lift

Purchasing a scissor lift involves several considerations to ensure you select the right equipment for your needs. One of the primary factors is the maximum height the lift can reach, which should align with the requirements of your projects.

Another critical factor is the lift’s weight capacity. It’s essential to choose a model that can safely support the combined weight of workers, tools, and materials. Additionally, consider the power source—electric models are suitable for indoor use, while diesel models are better for outdoor applications.

Other considerations include the size of the platform, ease of maneuverability, and maintenance requirements. It’s also advisable to look for a reputable manufacturer that offers good after-sales support and warranty options. By carefully evaluating these factors, you can select a scissor lift that enhances your operational efficiency and safety.