Buying Guide for Scissor Lifts

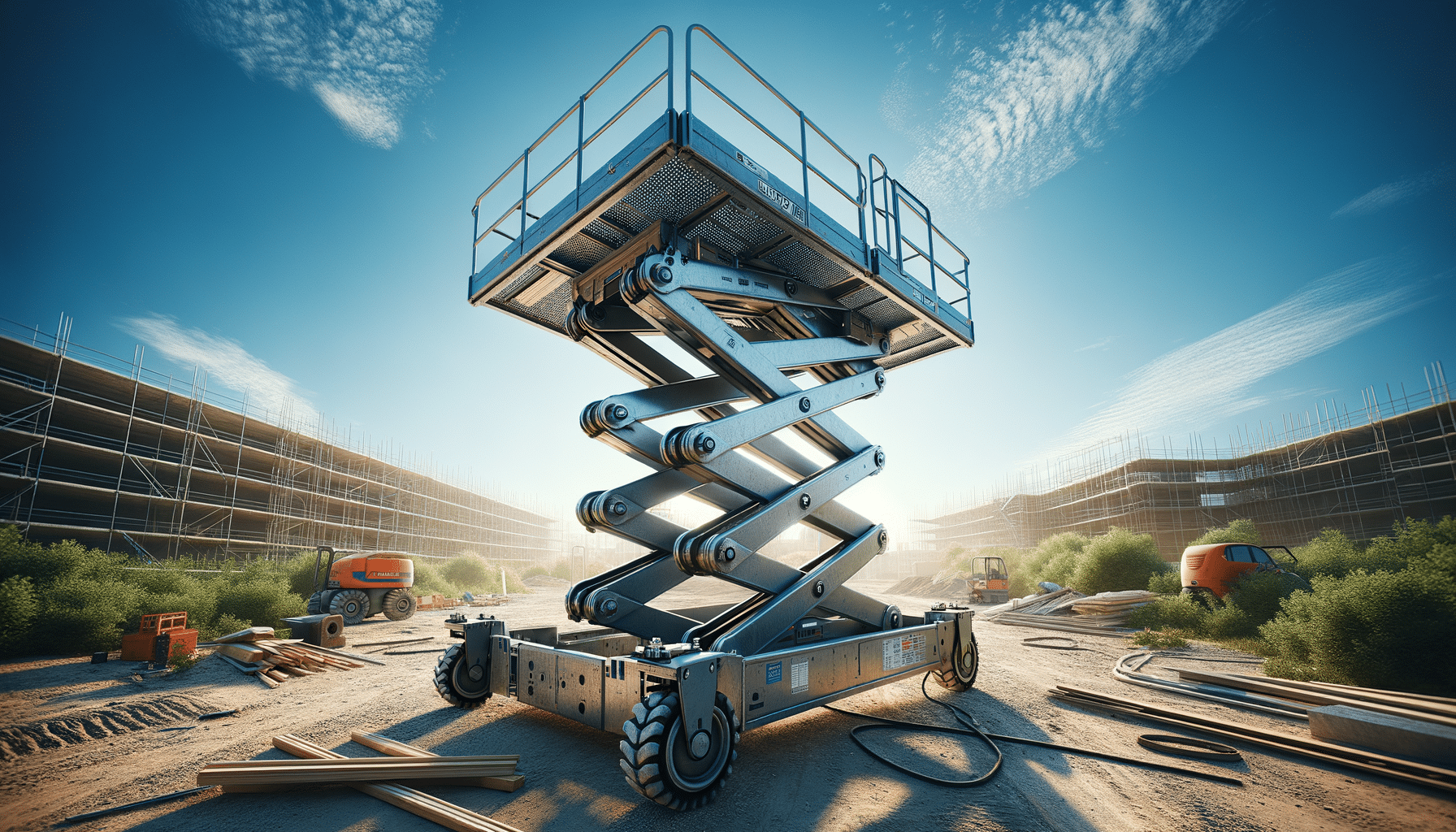

Introduction to Scissor Lifts

Scissor lifts are versatile and essential tools in various industries, offering a stable and efficient solution for reaching elevated work areas. Known for their unique X-shaped design, these lifts provide a reliable platform for tasks that require height access, such as maintenance, construction, and warehousing. Understanding the key features and benefits of scissor lifts can help businesses make an informed decision when purchasing this equipment.

The significance of scissor lifts lies in their ability to enhance productivity and safety. With a robust structure and straightforward operation, they minimize the risks associated with working at heights. This article delves into the different aspects of scissor lifts, providing valuable insights for potential buyers.

Types of Scissor Lifts

Scissor lifts come in various types, each tailored to specific applications and environments. The primary categories include electric, diesel, and rough terrain scissor lifts. Electric scissor lifts are ideal for indoor use, offering a quieter operation and zero emissions. They are perfect for tasks in confined spaces, such as warehouses or indoor construction sites.

Diesel scissor lifts, on the other hand, are designed for outdoor use. They offer more power and can handle rougher terrains, making them suitable for construction sites and outdoor projects. Their robust engines allow for greater height and weight capacities, accommodating more demanding tasks.

Rough terrain scissor lifts are built to navigate uneven surfaces, featuring larger tires and enhanced stability. They are equipped with powerful engines and are often used in challenging outdoor environments where standard lifts might struggle.

When choosing a scissor lift, consider the environment in which it will be used. Each type offers unique advantages, ensuring that the equipment meets the specific needs of your project.

Key Features of Scissor Lifts

Scissor lifts are renowned for their outstanding features that enhance functionality and safety. One of the most notable features is their X-shaped design, which provides stability and balance when extended. This design ensures that the platform remains secure, even at maximum height.

Another critical feature is the ease of operation. Scissor lifts are user-friendly, with intuitive controls that allow operators to focus on the task at hand. Many models come equipped with advanced safety features, such as emergency stop buttons, overload sensors, and guardrails, ensuring a safe working environment.

Additionally, scissor lifts offer varying platform sizes to accommodate different tasks. Some models come with extendable platforms, providing additional workspace and flexibility. This adaptability makes them suitable for a wide range of applications, from maintenance work to large-scale construction projects.

Overall, the features of scissor lifts contribute to their efficiency and reliability, making them a valuable asset in any setting that requires elevated access.

Safety Considerations When Using Scissor Lifts

Safety is paramount when operating scissor lifts, as working at heights poses inherent risks. It is crucial to ensure that operators are adequately trained and familiar with the equipment before use. Proper training includes understanding the controls, safety features, and emergency procedures.

Pre-operation checks are essential to identify any potential hazards or malfunctions. Inspect the lift for any visible damage, check fluid levels, and ensure that all safety mechanisms are functioning correctly. Regular maintenance is also vital to keep the lift in optimal condition and reduce the risk of accidents.

When using a scissor lift, always adhere to the manufacturer’s guidelines and weight limits. Overloading the platform can compromise stability and safety. Additionally, ensure that the lift is used on a stable surface and that all guardrails are in place.

By prioritizing safety, businesses can significantly reduce the risk of accidents and create a safer working environment for their employees.

Choosing the Right Scissor Lift for Your Needs

Selecting the appropriate scissor lift depends on several factors, including the specific requirements of your project and the environment in which the lift will be used. Begin by assessing the maximum height needed for your tasks and choose a lift that can comfortably reach that level.

Consider the weight capacity of the lift, ensuring it can support the combined weight of the equipment and personnel. Evaluate the power source that best suits your needs—electric lifts for indoor use and diesel or rough terrain lifts for outdoor applications.

It is also essential to factor in the lift’s portability and ease of transport, especially if it will be moved between different job sites. Some models come with features like foldable rails or compact designs for easier transportation.

Finally, consider any additional features that might enhance efficiency, such as extendable platforms or advanced control systems. By carefully evaluating these aspects, businesses can invest in a scissor lift that aligns with their operational needs and enhances productivity.