Buying Guide for Scissor Lifts

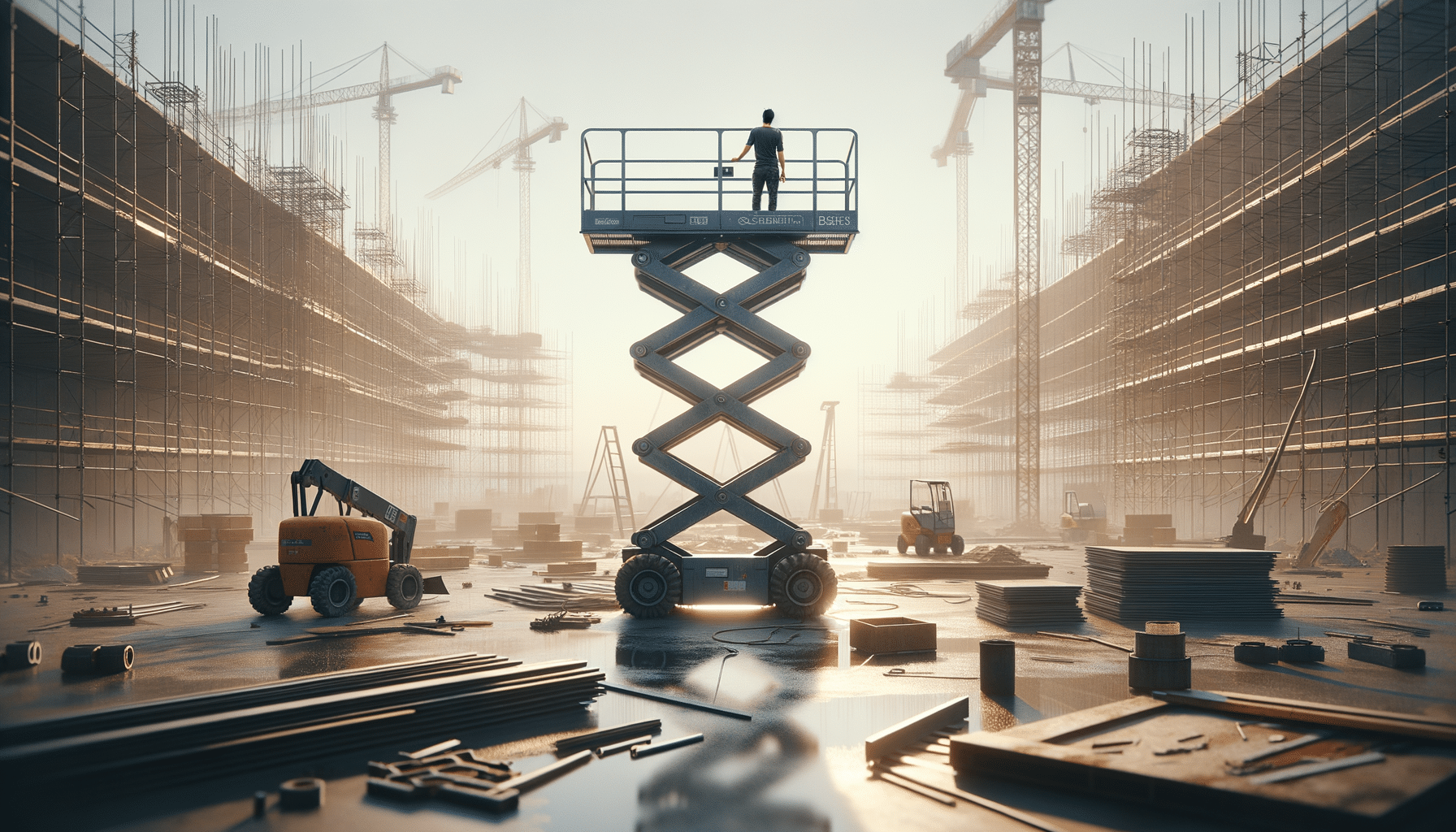

Understanding the Scissor Lift: A Fundamental Overview

The scissor lift is a versatile piece of equipment used across various industries for lifting workers and materials to different heights. Its distinctive feature is the crisscrossing metal supports, which expand and contract in a scissor-like fashion, allowing for smooth vertical movement. This unique design makes it an indispensable tool in construction, maintenance, and warehousing, where reaching elevated areas safely and efficiently is paramount.

One of the primary advantages of using a scissor lift is its stability. The wide base and sturdy construction provide a secure platform, reducing the risk of accidents. Additionally, its compact design makes it suitable for both indoor and outdoor use, navigating through tight spaces with ease. The scissor lift is also renowned for its user-friendly operation, with intuitive controls that enable operators to manage the lift’s height and movement precisely.

Scissor lifts come in various sizes and capacities, catering to different operational needs. From lightweight models for indoor maintenance tasks to heavy-duty lifts capable of handling large loads on construction sites, there is a scissor lift for virtually every requirement. As safety and efficiency are crucial in any work environment, investing in a scissor lift can significantly enhance productivity while ensuring worker safety.

Key Features and Benefits of Scissor Lifts

Scissor lifts offer a range of features that contribute to their widespread use. One of the most notable is their ability to provide a stable and elevated work platform. This stability is largely due to the lift’s X-shaped design, which evenly distributes weight and minimizes swaying, even at maximum height. This ensures a secure working environment, allowing tasks to be completed with confidence.

Another key feature is the lift’s maneuverability. Despite their size, many scissor lifts are designed to be easily moved and positioned, thanks to features like swivel wheels and compact dimensions. This makes them ideal for indoor use, where space may be limited, or for navigating complex outdoor terrain.

Scissor lifts are also equipped with safety mechanisms such as emergency stop buttons and guardrails, further enhancing their safety profile. Many models offer additional features, including non-marking tires for use on delicate floors and extendable platforms for increased reach and workspace.

Beyond these practical features, the use of a scissor lift can lead to increased productivity. By reducing the time and effort required to reach elevated work areas, tasks can be completed more efficiently, ultimately saving time and reducing labor costs.

Choosing the Right Scissor Lift for Your Needs

Selecting the right scissor lift involves considering several factors to ensure it meets your specific needs. The first consideration is the lift’s height capacity. Depending on the tasks you plan to undertake, you will need a lift that can reach the necessary heights safely. It’s important to choose a model that not only meets your current requirements but also offers flexibility for future projects.

Another crucial factor is the lift’s weight capacity. Ensure that the model you choose can handle the combined weight of the operators, tools, and materials. Overloading a lift can compromise safety and performance, so it’s essential to choose a model with an appropriate weight limit.

The environment in which the lift will be used is also a key consideration. For indoor use, compact electric models with non-marking tires are ideal. For outdoor projects, diesel or gas-powered lifts with robust tires are better suited to handle uneven terrain.

Finally, consider the lift’s ease of use and maintenance requirements. Opt for a model with straightforward controls and minimal maintenance needs to ensure smooth operation and longevity.

Safety Considerations When Operating a Scissor Lift

Safety is a top priority when operating a scissor lift. Proper training and adherence to safety guidelines are essential to prevent accidents and ensure a secure working environment. Before using a scissor lift, operators should undergo comprehensive training to understand the equipment’s controls, features, and safety protocols.

Regular maintenance checks are crucial to ensure the lift’s mechanical components are in good working order. This includes inspecting the hydraulic system, brakes, and emergency stop functions. Any signs of wear or damage should be addressed immediately to prevent potential hazards.

When using a scissor lift, it’s important to follow safety guidelines such as wearing appropriate personal protective equipment (PPE), including hard hats and harnesses. Operators should also be aware of their surroundings, especially when working near power lines or in areas with limited visibility.

Additionally, it’s vital to adhere to the manufacturer’s guidelines regarding load limits and operational procedures. Overloading the lift or using it on unstable surfaces can lead to dangerous situations. By prioritizing safety, operators can ensure efficient and secure use of scissor lifts in any environment.

Maintenance and Care for Longevity

Proper maintenance and care are essential to ensure the longevity and reliable performance of a scissor lift. Regular inspections and servicing can prevent breakdowns and extend the lifespan of the equipment, providing a better return on investment.

Routine maintenance tasks include checking hydraulic fluids, inspecting hoses and connections for leaks, and ensuring all moving parts are lubricated. It’s also important to keep the lift clean, removing any debris or dirt that could affect its operation. Regularly checking the battery or fuel levels, depending on the model, is also crucial to ensure the lift is ready for use when needed.

In addition to regular maintenance, operators should be vigilant for any signs of wear or damage during use. Any unusual noises, vibrations, or performance issues should be addressed promptly by a qualified technician. This proactive approach can prevent minor issues from becoming major problems, ensuring the lift remains safe and operational.

By investing time and effort into proper maintenance, businesses can maximize the efficiency and lifespan of their scissor lifts, ensuring they remain a valuable asset for years to come.