Why Polycarbonate Sheets Are a Practical Choice

Introduction to Polycarbonate Sheets

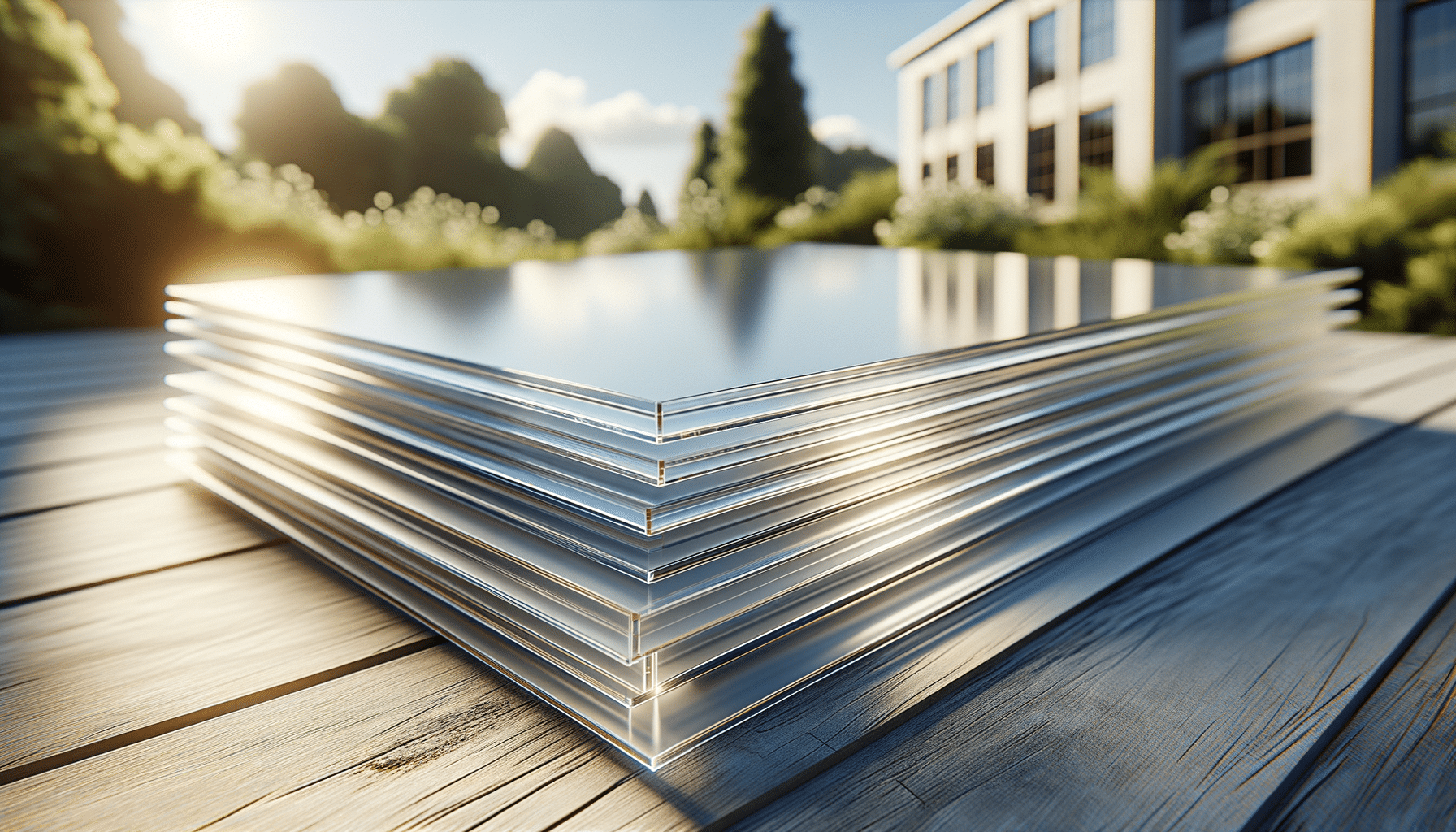

Polycarbonate sheets, often referred to as polycarbonate-board, have become a staple in various industries due to their exceptional properties. These sheets are made from a thermoplastic polymer that is known for its high impact resistance and transparency. This combination makes them a popular alternative to traditional materials like glass and acrylic. In an era where sustainability and efficiency are paramount, polycarbonate sheets offer a versatile solution that meets these demands.

One of the key reasons for the popularity of polycarbonate-board is its lightweight nature, which does not compromise its strength. This makes it ideal for applications where weight is a critical factor, such as in transportation and aerospace. Additionally, polycarbonate’s ability to withstand extreme temperatures and its UV resistance make it suitable for outdoor applications, providing longevity and durability in various environmental conditions.

In this article, we will explore the multifaceted applications of polycarbonate sheets, their benefits over other materials, and their role in modern construction and design. By understanding the unique qualities of polycarbonate-board, we can better appreciate its widespread use and its potential for future innovations.

Applications of Polycarbonate Sheets

The versatility of polycarbonate-board is evident in its wide range of applications across different industries. In the construction sector, these sheets are commonly used for skylights, greenhouses, and roofing panels. Their transparency allows for natural light to penetrate while providing insulation, making them an energy-efficient choice for builders and architects.

In the automotive industry, polycarbonate sheets are used for headlamp lenses and interior components. Their impact resistance ensures safety, while their lightweight nature contributes to fuel efficiency. Similarly, in the aerospace industry, polycarbonate’s strength-to-weight ratio is invaluable for aircraft windows and cockpit canopies.

Beyond industrial uses, polycarbonate sheets are also prevalent in everyday products such as eyeglass lenses, digital discs, and even smartphone cases. The material’s adaptability to different forms and functions highlights its importance in both high-tech and consumer markets.

Overall, the applications of polycarbonate-board are vast and varied, underscoring its role as a key material in modern manufacturing and design.

Advantages of Using Polycarbonate Sheets

Polycarbonate-board offers a range of advantages that make it a preferred choice over other materials like glass and acrylic. One of the most significant benefits is its impact resistance. Polycarbonate is virtually unbreakable, which makes it ideal for high-risk areas where safety is a concern, such as in security glazing and riot shields.

Another advantage is its lightweight nature. Polycarbonate sheets weigh significantly less than glass, which not only makes them easier to handle and install but also reduces structural load, leading to cost savings in construction projects.

Polycarbonate also offers excellent thermal insulation properties, which can contribute to energy efficiency in buildings. Its ability to filter out harmful UV rays while allowing natural light to pass through makes it a smart choice for environments that require both protection and visibility.

In terms of design flexibility, polycarbonate-board can be easily molded and shaped, allowing for creative and innovative architectural designs. Its availability in various colors and finishes further enhances its aesthetic appeal, making it a favorite among designers and architects.

Comparing Polycarbonate with Other Materials

When comparing polycarbonate-board with other materials like glass and acrylic, several differences stand out. Glass, for instance, is heavier and more prone to shattering, which can pose safety risks. While glass offers excellent clarity, polycarbonate provides similar transparency with added durability and impact resistance.

Acrylic is another alternative that is often compared to polycarbonate. While acrylic is less expensive, it is also more brittle and prone to cracking under stress. Polycarbonate, on the other hand, maintains its integrity under impact, making it a more reliable option for applications requiring high strength and resilience.

In terms of cost, polycarbonate may be more expensive upfront compared to acrylic. However, its longevity and reduced maintenance costs often make it a more economical choice in the long run. Additionally, polycarbonate’s superior thermal insulation properties can lead to energy savings, offsetting initial costs over time.

Ultimately, the choice between polycarbonate-board and other materials depends on the specific requirements of the project, including factors such as safety, durability, cost, and aesthetics.

Conclusion: The Future of Polycarbonate Sheets

As industries continue to evolve, the demand for materials that offer both performance and sustainability is increasing. Polycarbonate-board stands out as a material that meets these criteria, providing a balance of strength, versatility, and environmental friendliness.

With advancements in manufacturing processes and material science, the applications for polycarbonate sheets are likely to expand further. Innovations such as improved UV resistance and enhanced thermal properties could open new possibilities in areas like renewable energy and advanced construction techniques.

For businesses and consumers looking for a practical and reliable material, polycarbonate remains a strong contender. Its proven track record in various applications and its potential for future growth make it a material worth considering for a wide range of projects.